14

SeptemberWhat kinds of Surface Finishing Fit for CNC Machining Service?

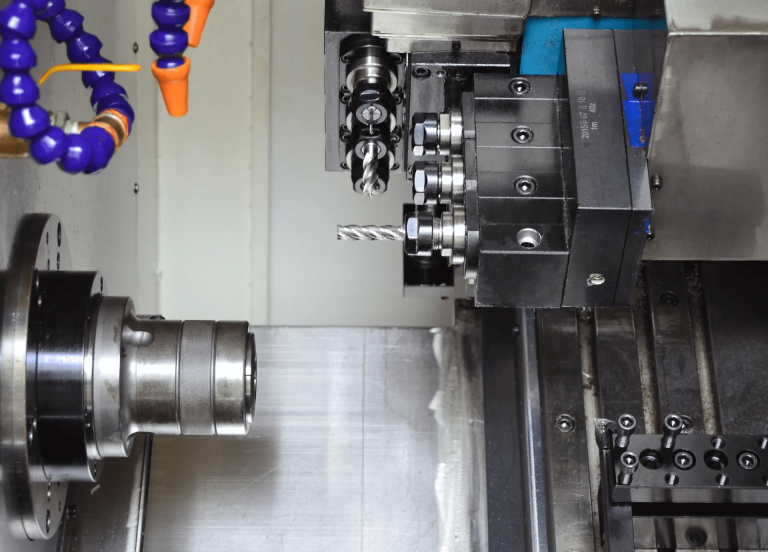

With CNC machining, small tolerance components of aproximatelly 0.025 mm is made & adequate information for metal or plastic components.

Since CNC models are subtractive, obvious equipment marks are going to be apparent on the surface area of a portion. Many post processing as well as finishing techniques are able to enhance the roughness of the entire body, put on opposition, along with graphic qualities.

As Machined Finish

The most popular CNC finishes for a good covering finish; initially can be as machined. These have small equipment marks which could be noticeable.

A finishing sawing pass is essential to reduce the roughness of a surface area. You need to observe this boosts the expense of generation due to extra machining stairs.

Additionally, machined areas are usually polished or even smoothed to enhance the aesthetics of theirs as well as area quality - smoothing and polishing consequence dimensional tolerances of elements.

Bead Blasting

This particular kind of completing gives a satin finish or maybe even matte surface to the machined factor. This way, it eliminates the equipment marks. The task entails bombarding the part with glass beads working with an atmosphere gun after which smoothing the surface area. In order to stay away from dimensional modifications, crucial surfaces or features may be hidden.

Anodizing Type two as well as three

Furthermore, there is Anodizing Type two which gives a corrosion resistant ceramic level to a part 's surface area. Also, it could be colored into a few colors. Sadly, it is obtainable just for Aluminum and Titanium. Anodizing sort three mounts oxidation and also a wear resistant ceramic level. It provides much more outstanding safety in comparison with kind 2.

Powdered Coating

Powdered covering can help bring oxidation and don finish to an element top. Likewise, it's increased influence opposition in comparison with anodizing. Also, it's a broad range of styles and also could be put on to nearly every metallic.

The procedure is akin to pressurized spray painting but utilizes dried up powdered as opposed to a fluid. For starters, areas are primed with a chromatin or even phosphating jacket to rise oxidation opposition.

It's subsequently coated with powdered utilizing an electrostatic squirt gun just before it's relieved at temperature that is high. The great point regarding powdered covering is the fact that various levels could be put on to create a fuller jacket.

What Industries Reap the benefits of CNC Machining Service?

CNC machining can help produce several complex components which are needed in numerous industries. Lots of industries are seeking CNC machining offerings to create and correctly layout pieces as well as products for numerous programs.

With regards to producing accuracy machined elements, a few industries have gained from CNC program.

CNC machining has helped enhance nearly every facet of the production operation. Nevertheless, several industries are deriving the best benefits through the implementation of its, & they include;

Defense/Military

The army business utilizes tough areas for simple maneuverability, maybe even in probably the harshest locations. The defense items have to comply with the government laws.

The market advantages from CNC machining for any rapid enhancements, producing areas from the strong substances in addition to durable styles. Furthermore, it can help make components that need small tolerances.

Aerospace

CNC machining is packaged in available in the aerospace market in improving serious components. The necessity for reliability as well as accuracy components makes CNC printer pieces the perfect option.

CNC machining offers a great option in the aerospace market for producing straightforward and sophisticated casing.

Consumer electronics Industry

Consumer electronic devices are gradually but steadily getting small, but effective. Additionally, they have to be lightweight and compact. Thus, the electric business is experiencing the advantages of CNC machining as many regions could be - Positive Many Meanings -.

Because of the higher procedure dependability via incorporated CAM fixes, applications may today be immediately place to creation.

Commercial

Every industrial solutions are of high quality and stay naturally competitive in rates. Provided that CNC machining is versatile, it enables the generation of various goods of various substances. CAD prototyping, 3d visuals, and modeling help lessen the production costs and also guide times.

Health Industry

The healthcare business utilizes personalized items to supply the requirements of individuals. The majority of the products are disposable to make sure they protect individuals from infectious diseases. Parts in the healthcare business call for severe accuracy which may be attained CNC machining program. Consistency, reliability, then repeatability are vital to fulfill the industries' demands that are high.

Just how does Sunrise Metal ensure of the quality control in CNC Machining Service?

Regardless of the market, quality management is vital. That's essential to supply industry requirements, industry regulations, and customer expectations.

With regards to CNC program, Sunrise Metal is in the roof of the game. The organization utilizes superior tools in the quality lab to help you in examining as well as evaluating the parts. Thus, there is an assurance of conference tough quality management requirements.

Quality management plays a crucial part of CNC as it guarantees products that are manufactured comply with needs. Additionally, it has helped reduce chances, stay away from defective items, enhance effectiveness, and also lessen cost and wastage. Thus, quality management is ideal for both manufacturers and customers.

Additionally, there's adequate competent team which do different jobs needed in each and every phase on the manner in which. Moreover, Sunrise Metal has excessive precision CMM gear of Carl Zeiss. Also, the amount of assessment from the sunrise staff is unparalleled.

Furthermore, Sunrise Metal tools a consistent quality management process, matching the combined efforts in quality assurance. It guarantees the demands the buyer and regulatory authorities are satisfied.

The quality assessment system can help find defects because of the layout as well as production process. Most procedures and controls are increased to encounter global standards.

That's additionally the situation with applications as well as teaching manuals. Furthermore, the task is continually assessed to satisfy the customer 's requirements and also enhance the quality of its.

The sophisticated measuring programs & tools are accustomed to evaluate sizes, hardness, tolerances, colors, and much more. Micrometers, Air Gage, along with CMM are several of the resources used in counting.

Furthermore, the business has purchased high quality QA test products. The gear has a X ray detection printer, a Coordinate Measuring Machine together with the Zeiss manufacturer, and much more.

When Sunrise Metal Receives an order, they look at the layout illustrations and also understand the industry of yours. For example, medical and military areas need exceptional accuracy, tight tolerance, excellent quality, along with complete security.

With Sunrise Metal, we realize the interaction is two way. Communication with clients is performed faster. As an outcome, both consumer and company have precise demands for merchandise performance and specification. When food isn't correct, an answer is covered immediately.

The full name of HJY Hardware is Shenzhen HongJingYuan Hardware and Plastic Products Co., Ltd. We were established in 1996 and officially registered in 2022. In these 20+ years, we are in our motherland: China, and are the partner of many leading companies. If you ask China’s leading companies for news from us, most companies will give us affirmation, but this does not mean that we are not doing well in the world. We also have very deep and long-term cooperation with many European and American companies. As a CNC machining service provider with a history of more than 20 years, we have provided unique customized CNC machining services to countless companies at home and abroad. We have produced countless precision CNC machining parts.

Contact

- Email Us:hjy@hongjingyuan.com

- Call Us: +86 136 0255 0692